Unleashing Creativity and Precision: The World of Laser Cutting

Laser cutting, an advanced and versatile technology, has been revolutionizing various industries, from fashion to engineering. This blog explores the fascinating world of laser cutting, diving into its applications, benefits, and the innovative opportunities it offers.

The Art of Laser Cutting

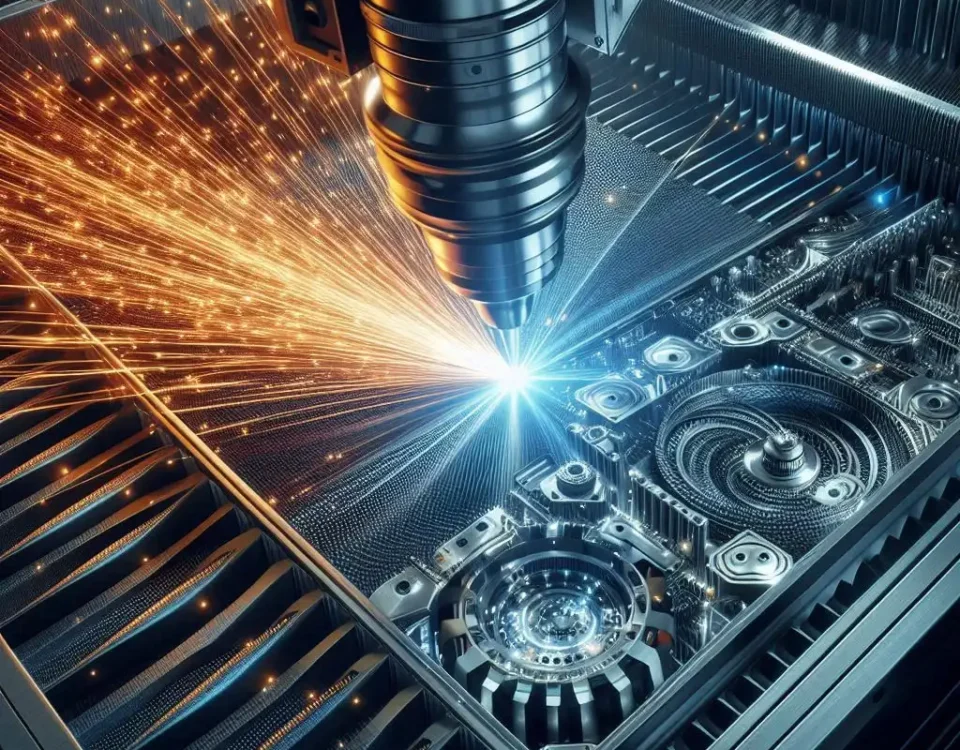

Precision Beyond Imagination

At its core, laser cutting is a method that uses a high-powered laser to cut or engrave materials with exceptional precision. The laser beam can be guided by computer-aided design (CAD) files to create intricate, detailed, and flawless cuts. This level of precision is unmatched by traditional cutting methods.

Applications Across Industries

From Fashion to Aerospace

Laser cutting is an incredibly versatile technology, finding applications in numerous industries. Here are a few areas where it’s making a significant impact:

- Fashion Industry: Designers use laser cutting to create intricate patterns and designs on fabrics, leather, and even acrylic, resulting in unique and eye-catching fashion pieces.

- Engineering and Manufacturing: In these fields, laser cutting is used to create intricate machine parts, delicate prototypes, and precise components, improving efficiency and accuracy.

- Signage and Advertising: Laser-cut signage and advertising materials stand out with their intricate details and clean edges.

- Architecture: Architectural models and intricate building components can be efficiently produced through laser cutting, allowing for complex designs to be realized.

- Personalized Products: From custom invitations to engraved gifts, laser cutting adds a personalized touch to a wide range of products.

Advantages of Laser Cutting

Why Choose Laser Over Other Methods?

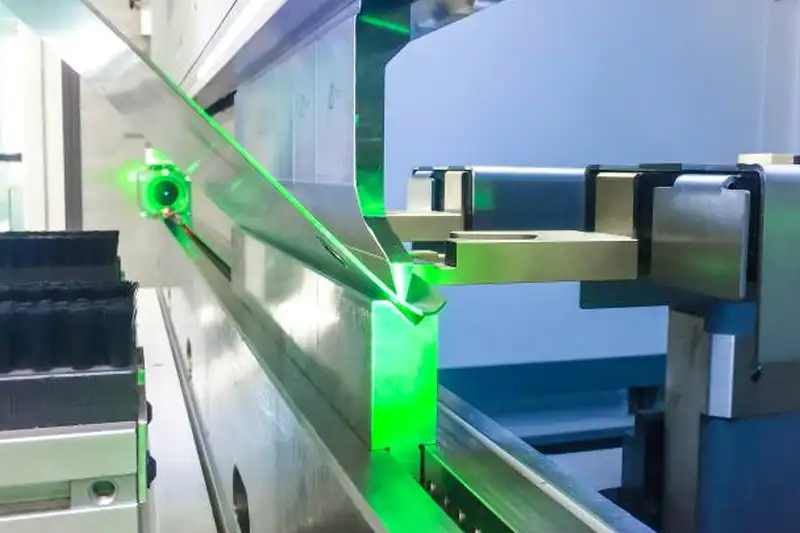

Laser cutting offers several advantages, making it a preferred choice in many applications:

- Precision: Laser cutting provides extremely fine cuts and intricate detailing, allowing for highly accurate results.

- Speed: The process is fast, especially when compared to traditional cutting methods.

- Minimal Material Waste: Laser cutting minimizes material wastage, making it an eco-friendly option.

- Versatility: It can work with a variety of materials, including metals, plastics, wood, and more.

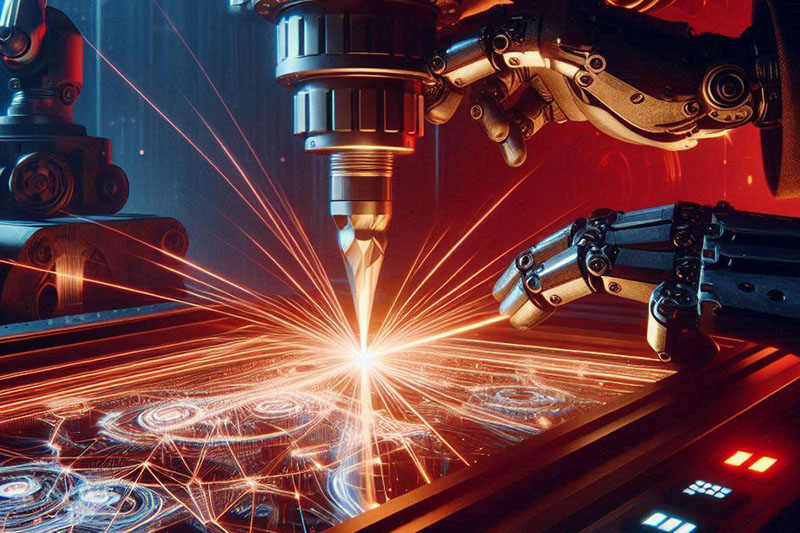

- Automation: Laser cutting can be automated, reducing the need for manual labor and increasing efficiency.

A World of Creative Possibilities

Innovation in Every Beam

Laser cutting opens up a world of creative possibilities. Whether you’re a designer, engineer, or artist, this technology empowers you to push the boundaries of what’s possible. Its precision and versatility make it a game-changer in various industries, allowing for the creation of intricate, unique, and highly detailed products.

Embrace Laser Cutting

Laser Cutting: Shaping the Future

As laser cutting technology continues to advance, its impact on various industries is set to grow. Whether you’re a professional looking to streamline your production process or an artist wanting to explore new creative horizons, laser cutting is a tool worth embracing. Stay tuned to our blog for more insights into this exciting world of precision and creativity.