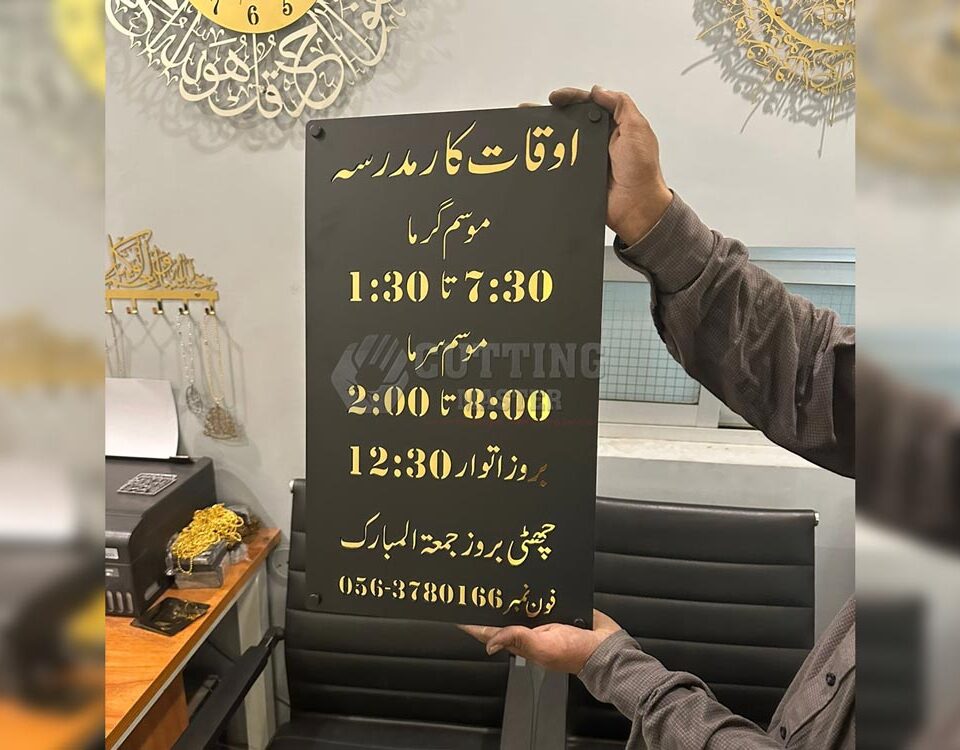

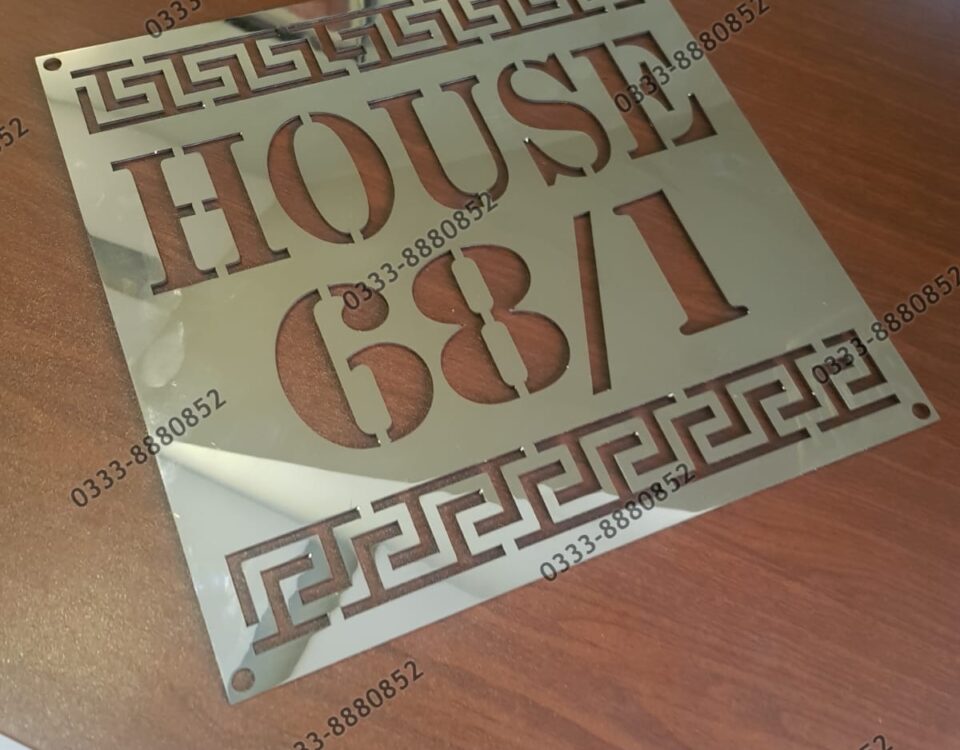

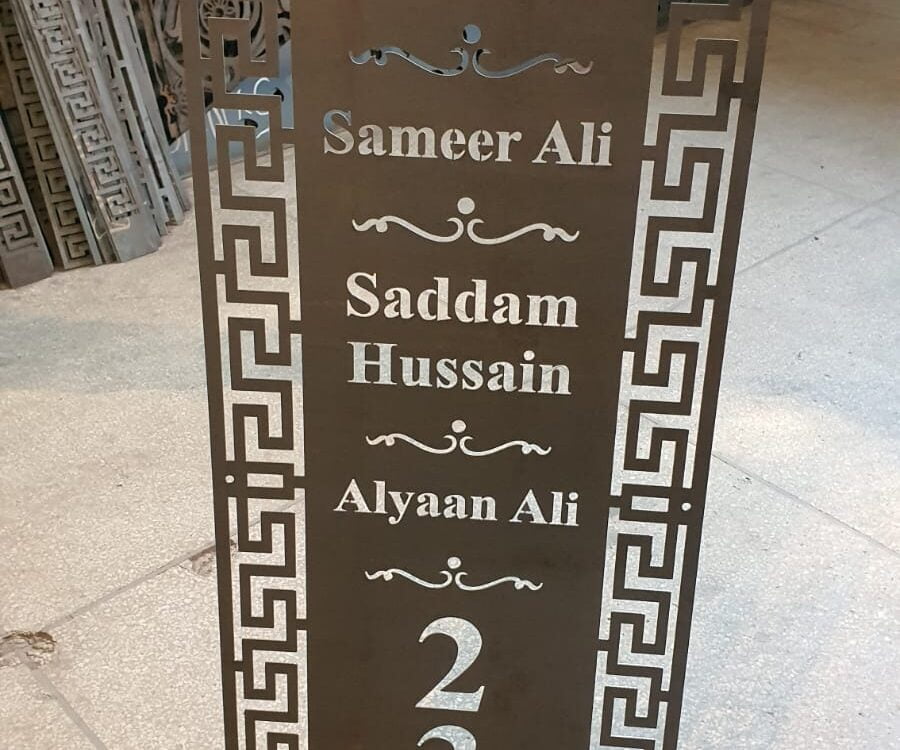

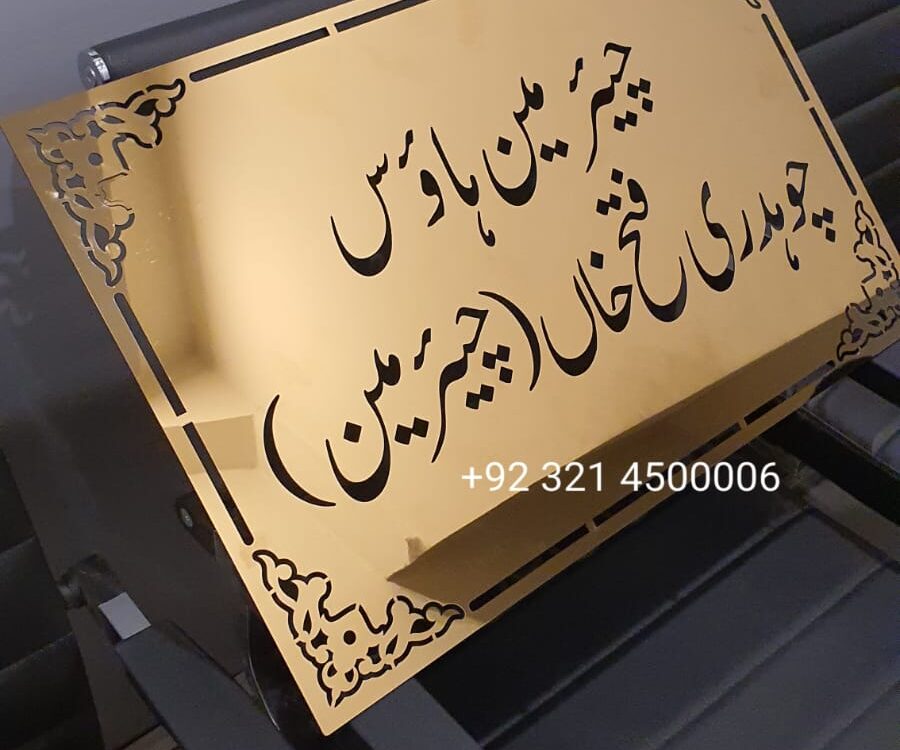

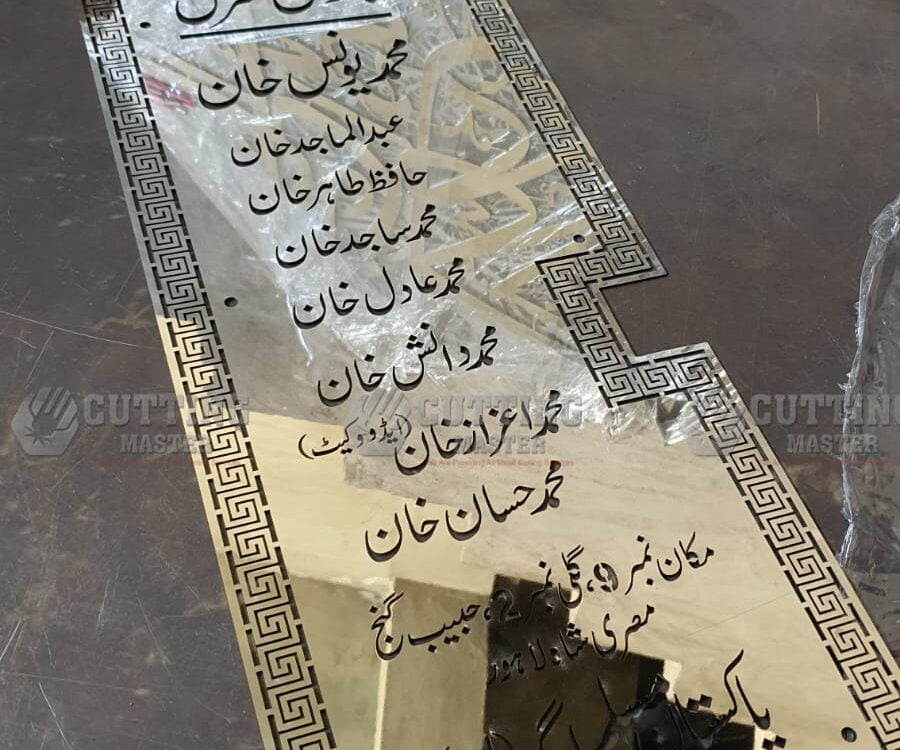

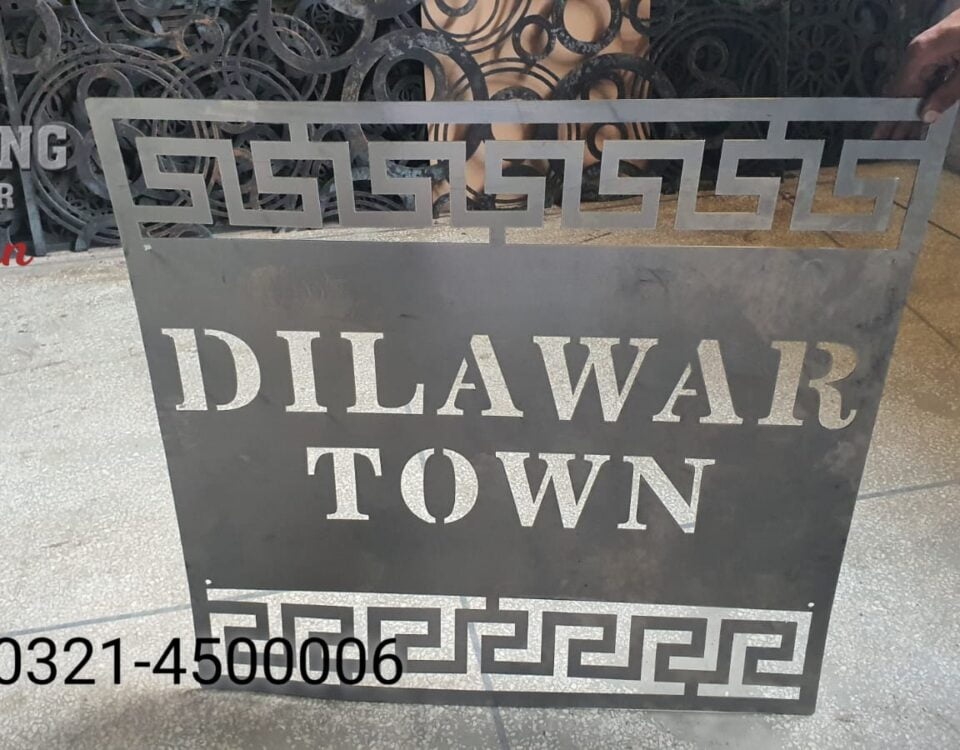

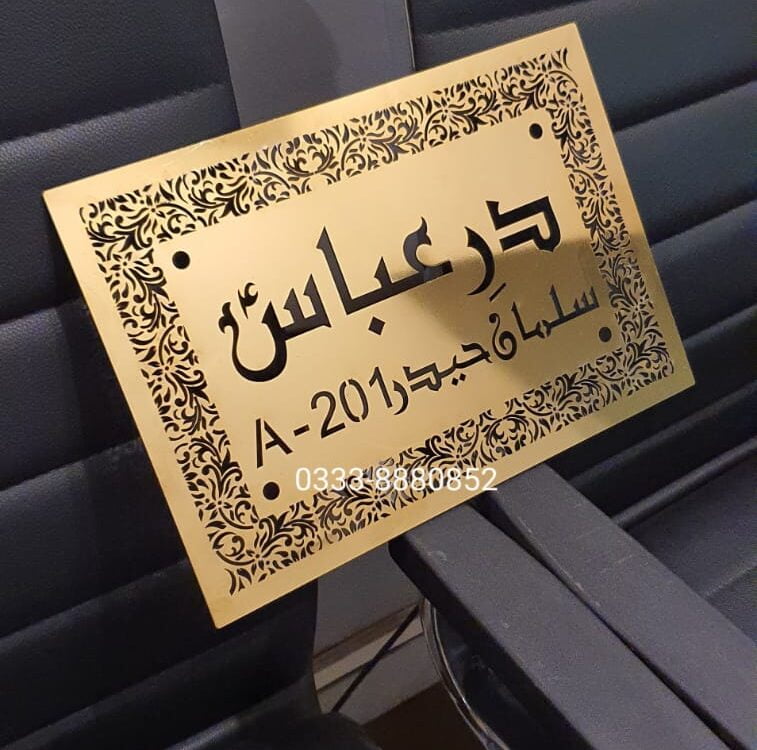

Laser Cut Nameplate

Nameplates Laser Cut Design

Durable and Long-Lasting

Metal nameplates are known for their durability and longevity. They are able to withstand harsh conditions, such as exposure to the elements, high temperatures, and heavy wear and tear. This makes them an ideal choice for products and equipment that will be used in industrial, construction, and other rugged environments. The laser-cut designs on these nameplates are also incredibly precise, ensuring that the labels remain legible for years to come.

Professional Appearance

The intricate designs that can be created with laser cutting technology provide a level of detail and precision that is unmatched by traditional metal nameplate manufacturing methods. This allows businesses to create custom designs that reflect their brand and add a touch of sophistication to their products and equipment. The high-end appearance of these nameplates is sure to impress customers and clients, and can help businesses stand out from their competition.

Versatile Applications

Metal nameplates with laser-cut designs can be used in a variety of applications, including product labeling, equipment identification, and safety signage. They are also commonly used in the aerospace, automotive, and medical industries, as well as in construction and manufacturing. With their versatility and durability, these nameplates are a cost-effective solution for businesses of all sizes and industries.

Easy to Read

The precise laser-cut designs on metal nameplates make them easy to read, even in low light or challenging environments. This is particularly important for safety signage and equipment identification, where clear and legible labels can help prevent accidents and errors. The high-quality materials used in metal nameplate manufacturing also ensure that the labels remain legible for many years, even with heavy use.

Environmentally Friendly

In addition to their many benefits, metal nameplates with laser-cut designs are also environmentally friendly. Unlike traditional metal nameplate manufacturing methods, laser cutting does not produce any harmful chemicals or waste. This makes it a sustainable choice for businesses that are looking to reduce their environmental impact.

In conclusion, metal nameplates with laser-cut designs are a durable, professional, and cost-effective solution for businesses of all sizes and industries. With their versatility, easy-to-read designs, and environmentally friendly manufacturing process, these nameplates are sure to provide a long-lasting and high-quality solution for your labeling and identification needs.

Advantages:

- Precision: Metal laser cutting technology provides precise cuts and edges, making it ideal for creating intricate designs and logos.

- Durability: Metal is strong and resistant to wear and tear, making metal laser-cut nameplates ideal for use in harsh environments.

- Versatility: Metal laser cut nameplates can be made from a variety of materials, including aluminum, stainless steel, and brass, allowing for different levels of durability and finish options.

- Customization: Metal laser cut nameplates can be designed to meet specific needs, with the option to add colors, textures, and graphics to create a unique and eye-catching display.

Process:

- Design: The first step in creating metal laser-cut nameplates is to create a design that meets the specific needs and requirements of the customer.

- Laser cutting: The metal is cut using a high-powered laser that is precise and efficient, allowing for intricate designs and precise cuts.

- Finishing: The metal is then finished to enhance its durability and appearance, with options including anodizing, powder coating, and polishing.

- Assembly: The final step is to assemble the metal laser cut nameplate, which may include adding a backing, mounting hardware, and any additional components as required.

Applications:

- Industrial: Metal laser cut nameplates are commonly used in industrial settings, where they are used to label equipment, machinery, and other components.

- Retail: Metal laser cut nameplates are also popular in retail environments, where they are used to display product information, brand logos, and other important details.

- Commercial: Metal laser-cut nameplates are often used in commercial settings, such as offices and hotels, where they are used to display names, labels, and other information.

- Personal: Metal laser cut nameplates can also be used for personal applications, such as labeling tools, personal items, and even as decorative pieces.

In conclusion, metal laser-cut nameplates are a versatile, durable, and professional way to display information. With the ability to customize designs and finishes, and a wide range of applications, metal laser-cut nameplates are a popular choice for many businesses and organizations.