Frequently asked questions about metal laser cutting

1What is metal laser cutting?

Metal laser cutting is a process that uses a high-powered laser beam to cut and shape metal materials with precision.

2What types of metals can be cut using laser cutting?

Laser cutting can be used to cut a wide variety of metals including stainless steel, aluminum, copper, brass, and more.

3What are the advantages of using laser cutting for metal?

Laser cutting offers several advantages including high precision, minimal material waste, and fast cutting speeds.

4What are the disadvantages of using laser cutting for metal?

Laser cutting can be more expensive than other cutting methods, and may not be suitable for thicker materials.

5What thickness of metal can be cut using laser cutting?

The thickness of metal that can be cut using laser cutting depends on the power of the laser and the type of metal being cut. Generally, laser cutting can cut up to 20mm thickness of steel.

6What is the maximum size of metal that can be cut using laser cutting?

The maximum size of metal that can be cut using laser cutting depends on the size of the laser cutting machine. At Cutting Master, we have machines capable of cutting up to 3000mm x 1500mm.

7What is the accuracy of laser cutting?

Laser cutting can achieve very high levels of accuracy, typically within 0.1mm.

8What is the cost of laser cutting?

The cost of laser cutting depends on several factors including the size and thickness of the metal, the complexity of the design, and the quantity of pieces being cut.

9How long does it take to complete a laser cutting project?

The time it takes to complete a laser cutting project depends on the size and complexity of the project. At Cutting Master, we can provide an estimate of the time required once we have seen the design and know the scope of the project.

10Can laser cutting be used for custom designs?

Yes, laser cutting is a great option for custom designs, as it can cut intricate shapes and designs with high precision.

11What file types are accepted for laser cutting?

We accept a variety of file types including DXF, DWG, and AI files.

12What is the turnaround time for laser cutting projects?

The turnaround time for laser cutting projects depends on the size and complexity of the project, as well as our current workload. At Cutting Master, we strive to complete projects as quickly as possible without compromising on quality.

13Can laser cutting be used for large scale production?

Yes, laser cutting can be used for large scale production, and is often used in industries such as automotive, aerospace, and electronics.

14Can laser cutting be used for small scale production?

Yes, laser cutting can be used for small scale production as well, and is a great option for prototyping and creating custom parts.

15What safety precautions are taken during laser cutting?

At Cutting Master, we take safety very seriously and ensure that all appropriate safety precautions are taken, including wearing protective gear and having fire suppression systems in place.

16What is the maintenance required for laser cutting machines?

Laser cutting machines require regular maintenance to ensure optimal performance and longevity. At Cutting Master, we have a team of technicians who perform regular maintenance on our machines.

17What other services does Cutting Master offer?

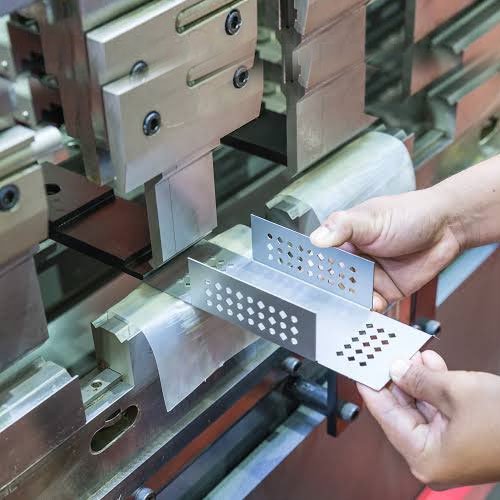

In addition to laser cutting, Cutting Master offers a variety of services including CNC bending, welding, and powder coating.