Unlock Precision with Plasma Cutting: High-Speed Metal Fabrication

September 24, 2024

Unlock Precision with CNC Bending: Transform Your Projects Today!

October 5, 2024In the world of manufacturing, precision and speed are paramount. Whether you’re creating intricate designs or producing large-scale components, Fiber Laser Cutting offers the ideal solution for achieving exceptional quality with unmatched efficiency. At Cutting Master, we specialize in providing top-of-the-line fiber laser cutting services tailored to meet the unique needs of our clients.

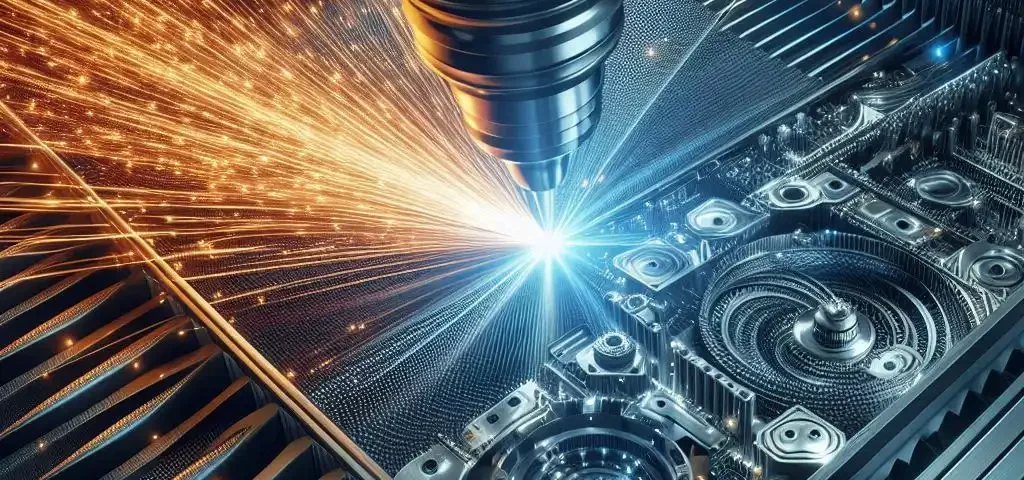

What is Fiber Laser Cutting?

Fiber laser cutting is a state-of-the-art technology that uses a high-powered laser beam to cut through materials with remarkable accuracy. Unlike traditional cutting methods, fiber lasers produce a highly focused beam that allows for precise cutting, even on the most complex shapes and patterns. This technology is particularly effective on metals, offering superior edge quality and minimal material waste.

Why Choose Fiber Laser Cutting?

Fiber laser cutting is rapidly becoming the go-to choice for industries that require high precision and efficiency. Here’s why:

- High Precision: The fine focus of the laser beam ensures that even the most intricate designs are cut with exactness, leaving smooth edges without the need for additional finishing.

- Speed and Efficiency: Fiber lasers cut faster than traditional methods, making it an ideal choice for both large production runs and custom projects.

- Versatility: Capable of cutting a wide range of materials, including stainless steel, aluminum, and copper alloys, fiber laser cutting adapts to various project needs.

- Cost-Effective: The efficiency of the cutting process reduces material waste, leading to cost savings, especially in high-volume production.

Applications of Fiber Laser Cutting

Fiber laser cutting is widely used across various industries due to its versatility and precision. Some common applications include:

- Automotive Parts: Precision cutting for parts like brackets, panels, and exhaust systems.

- Aerospace Components: Creating intricate components with exact tolerances.

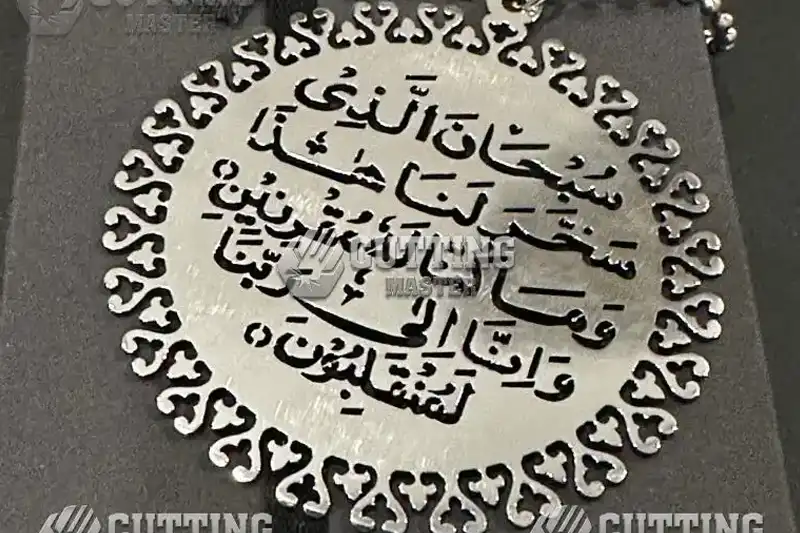

- Architectural Designs: Crafting detailed designs for decorative panels, gates, and more.

- Electrical Enclosures: Cutting metal enclosures with precise openings for switches and connectors.

- Custom Art and Signage: Producing unique, detailed designs for art pieces and commercial signage.

How Cutting Master Can Help

At Cutting Master, we leverage the power of fiber laser technology to deliver exceptional results for your projects. Here’s how we stand out:

- Advanced Technology: Our state-of-the-art fiber laser machines ensure the highest level of precision and speed, allowing us to handle both simple and complex projects with ease.

- Experienced Team: Our team of skilled professionals brings years of experience to every project, ensuring that your specifications are met with perfection.

- Flexible Production: Whether you need a single prototype or a large production run, we can scale our services to meet your needs, all while maintaining the highest standards of quality.

Case Study: Enhanced Efficiency for an Electronics Manufacturer

One of our clients, a leading electronics manufacturer, required precise cutting for metal enclosures used in their products. By switching to our fiber laser cutting services, they not only achieved the precision they needed but also reduced their production time by 40%. The increased efficiency allowed them to meet tight deadlines and improve their overall production workflow.

FAQs About Fiber Laser Cutting

1. What materials can fiber laser cutting handle?

Fiber laser cutting is particularly effective on metals like stainless steel, aluminum, and copper alloys.

2. How does fiber laser cutting compare to CO2 laser cutting?

Fiber lasers are more efficient and faster, especially for cutting metal, making them a preferred choice for many industrial applications.

3. Can fiber laser cutting handle complex designs?

Yes, the precision of fiber lasers allows for cutting even the most intricate designs with high accuracy.

4. Is there a minimum order quantity?

No, we cater to both small and large production runs, providing the same level of quality and service regardless of the order size.

5. What industries benefit most from fiber laser cutting?

Industries such as automotive, aerospace, electronics, and architecture benefit greatly from the precision and efficiency of fiber laser cutting.