The Top Benefits of CNC Bending for Industrial Projects

November 5, 2024

The Advantages of Using Laser Cutting Services for Custom Projects

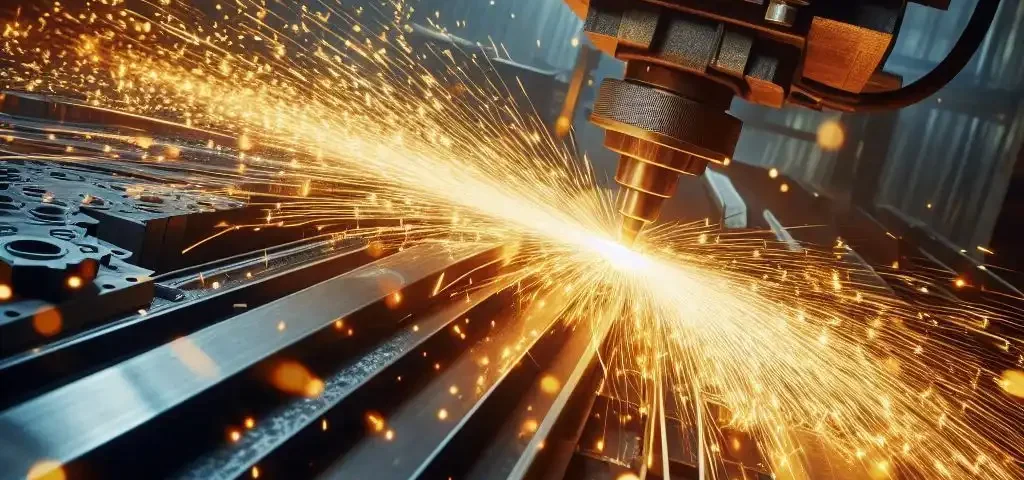

November 15, 2024When it comes to cutting through thick, tough materials with ease, Flame Cutting stands out as a tried-and-true method. This powerful technique, which utilizes a high-temperature flame to slice through metal, is essential for heavy-duty applications where precision and efficiency are crucial. At Cutting Master, we offer top-notch flame cutting services that deliver accurate results, even on the most challenging materials.

What is Flame Cutting?

Flame cutting, also known as oxy-fuel cutting, is a process that involves using an oxygen-fuel mixture to generate a flame hot enough to cut through metal. The intense heat produced by the flame melts the material, and a jet of pure oxygen is then used to blow away the molten metal, creating a precise cut. This method is particularly effective for cutting thick metal plates and is widely used in industries requiring heavy-duty fabrication.

Advantages of Flame Cutting

Flame cutting offers several benefits that make it an ideal choice for specific applications:

- Capable of Cutting Thick Materials: Flame cutting can easily cut through metal plates up to several inches thick, making it perfect for heavy-duty applications.

- Cost-Effective for Large-Scale Projects: For projects involving large quantities of thick steel, flame cutting is often more economical compared to other cutting methods.

- Versatile and Flexible: Flame cutting can be used on a variety of metals, including carbon steel and low-alloy steels, making it a versatile option for many industries.

- Precision in Heavy-Duty Applications: Despite its powerful nature, flame cutting provides clean, precise cuts that are essential for high-quality fabrication.

Applications of Flame Cutting

Flame cutting is a go-to method for industries that require robust cutting capabilities. Common applications include:

- Construction: Cutting steel beams, columns, and other structural components for buildings and infrastructure.

- Shipbuilding: Fabricating large steel sections used in ship hulls, decks, and other maritime structures.

- Manufacturing Heavy Machinery: Cutting thick metal parts that are used in the production of heavy equipment and machinery.

- Steel Fabrication: Creating custom steel components for various industrial applications, including pipelines, tanks, and frames.

- Repair and Maintenance: Cutting out sections of metal for repair work in construction, automotive, and heavy industries.

Why Choose Cutting Master for Flame Cutting?

At Cutting Master, we bring a wealth of experience and state-of-the-art equipment to our flame cutting services, ensuring that we meet the highest standards of quality and efficiency:

- Expert Team: Our team of skilled professionals has extensive experience in flame cutting, guaranteeing precise results on every project.

- Advanced Equipment: We use modern, well-maintained flame cutting machinery that ensures clean cuts and consistent performance, even on the toughest materials.

- Custom Solutions: Whether you need a single custom piece or a large production run, we tailor our flame cutting services to meet your specific requirements.

Case Study: Streamlining Construction Projects with Efficient Flame Cutting

One of our clients, a large construction firm, needed to cut thick steel beams for a new infrastructure project. By choosing Cutting Master’s flame cutting services, they were able to complete the cutting process quickly and accurately, which helped keep the project on schedule and within budget. The precision and speed of our flame cutting services significantly reduced the time and labor costs associated with the project.

FAQs About Flame Cutting

1. What materials are best suited for flame cutting?

Flame cutting is most effective on carbon steel and low-alloy steels, especially when cutting thick plates.

2. How thick can the material be for flame cutting?

Flame cutting is capable of cutting through metal plates several inches thick, making it ideal for heavy-duty applications.

3. Is flame cutting more cost-effective than other cutting methods?

For large-scale projects involving thick steel, flame cutting is often more economical due to its speed and efficiency.

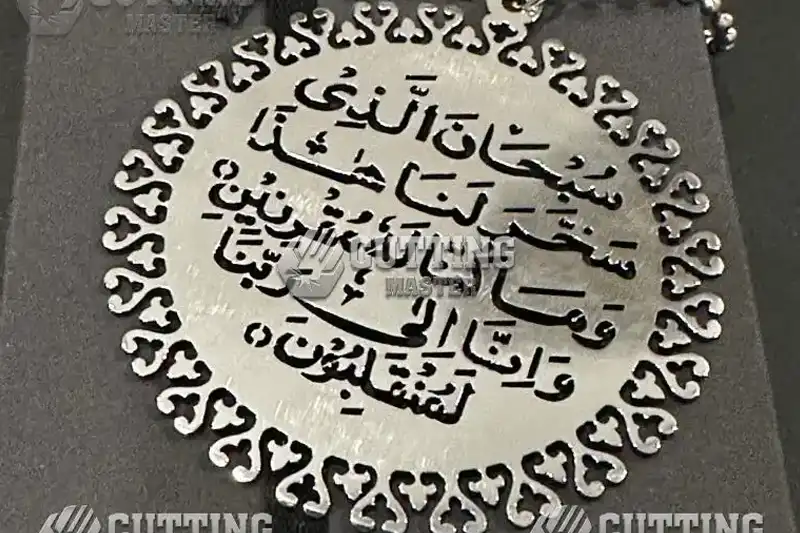

4. Can flame cutting be used for intricate designs?

While flame cutting excels in cutting thick materials, it may not be the best choice for highly intricate designs where fine detail is required.

5. What industries commonly use flame cutting?

Flame cutting is widely used in construction, shipbuilding, heavy machinery manufacturing, steel fabrication, and repair and maintenance industries.