Boost Your Business Efficiency with CNC Bending Services

December 5, 2024

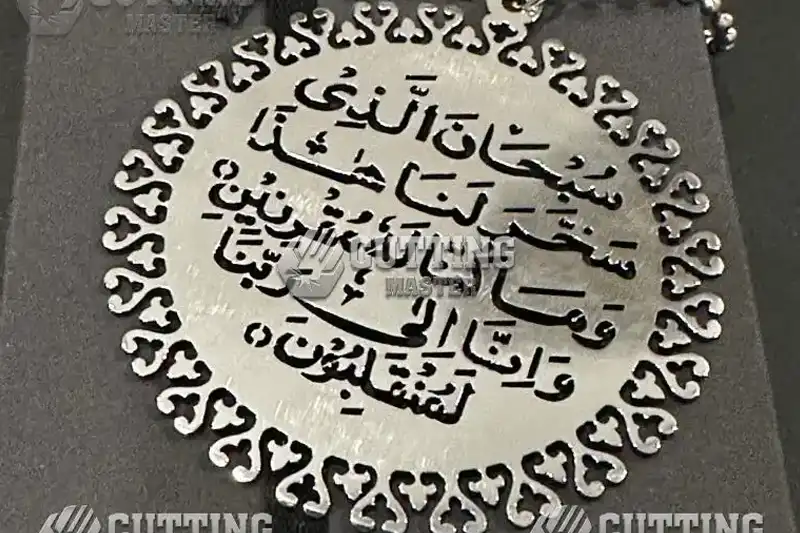

Create Stunning Spaces with Laser-Cut Room Dividers

December 25, 2024Introduction

In the manufacturing world, time and accuracy are key to success. Laser cutting services can significantly improve your production efficiency by reducing turnaround times, minimizing waste, and increasing precision. Let’s explore how laser cutting services from Eagle Machine Tools can help your business boost productivity.

How Laser Cutting Increases Efficiency

- Speed

Laser cutting is far quicker than traditional methods like mechanical cutting or sawing. The focused laser can move at high speeds without compromising on accuracy, allowing for faster production cycles. - Reduced Setup Time

Unlike other cutting methods that require multiple tools for different materials, laser cutting can handle various materials and thicknesses with just a quick programming change. This reduces downtime between projects and maximizes your output. - Consistent Quality

Laser cutting machines are controlled by CNC technology, ensuring that each piece is cut with the same level of precision, no matter how many units are produced. This guarantees uniformity, which is especially important for industries such as automotive and manufacturing. - Lower Labor Costs

Laser cutting reduces the need for manual intervention, minimizing labor costs and reducing the chance of human error. This makes it a cost-effective option for businesses looking to streamline their production process.

Real-World Example: Manufacturing Industry

A manufacturing company that shifted to laser cutting for its production lines saw a 40% reduction in turnaround times and a significant improvement in the quality of their metal components. By cutting labor costs and improving efficiency, they were able to scale their production without increasing operational expenses.

Link to Related Services: Explore CNC Bending for Enhanced Precision

FAQs

- How fast is laser cutting compared to traditional methods?

Laser cutting is significantly faster than traditional methods like mechanical cutting or sawing. - What industries benefit the most from increased production efficiency?

Manufacturing, automotive, and construction industries see the most benefit from laser cutting’s increased efficiency. - Can laser cutting handle high-volume orders?

Yes, laser cutting is highly scalable, making it perfect for high-volume production runs. - What are the labor cost savings with laser cutting?

Laser cutting reduces manual labor, leading to lower overall labor costs. - Is laser cutting consistent across large production runs?

Absolutely. CNC-controlled laser cutting ensures consistent quality, even across large production runs.