Unveiling the Growth and Potential of the Laser Cutting Industry in Pakistan

January 22, 2024

Laser Cutting Business Mastery: Launching Your Venture in Pakistan

February 10, 2024In recent years, laser cutting has emerged as a game-changer in the manufacturing industry. This cutting-edge technology utilizes a highly focused laser beam to cut and shape various materials with unparalleled precision. From intricate designs to large-scale productions, laser cutting has become a go-to method for creating a diverse range of products.

Understanding the Laser Cutting Process

Laser cutting involves the use of a laser beam to melt, burn, or vaporize materials. The process begins with a digital file that dictates the precise path the laser will follow. This level of accuracy allows for the creation of detailed and complex patterns, making it ideal for crafting customized products.

Advantages of Laser Cutting

- Precision and Accuracy: Laser cutting ensures a level of precision that is hard to achieve with traditional methods.

- Versatility: It can cut through various materials, including metals, wood, acrylic, and more.

- Speed and Efficiency: The laser cutting process is swift, contributing to efficient production cycles.

- Minimal Material Waste: The focused beam minimizes material wastage, making it a sustainable option.

Applications Across Industries

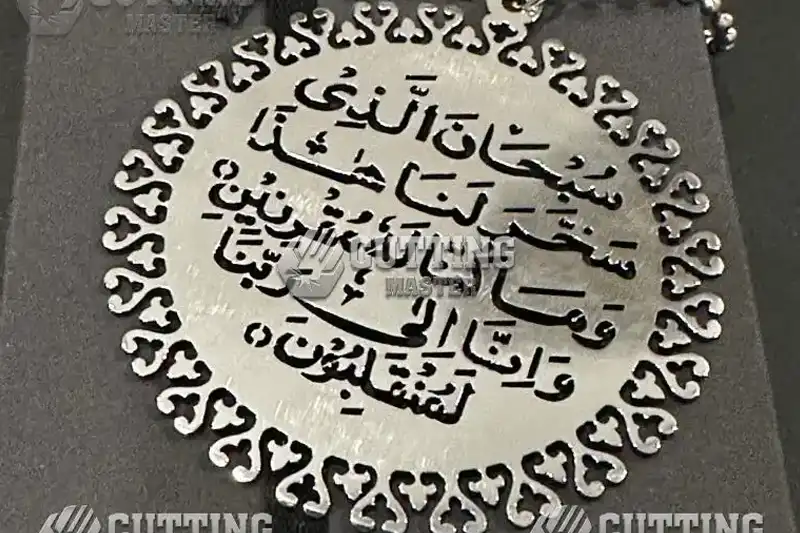

1. Art and Décor

- Laser-cut art pieces and decorative items add a touch of sophistication to interiors.

- Intricate patterns and detailed designs can be easily achieved.

2. Fashion and Accessories

- From leather to fabric, laser cutting enables the creation of unique fashion pieces.

- Delicate patterns and personalized designs are becoming increasingly popular.

3. Electronics and Gadgets

- Precision in cutting is crucial for the creation of intricate electronic components.

- Laser cutting ensures clean edges and accurate dimensions.

4. Architectural Models

- Architects utilize laser cutting to create detailed models with precision.

- It aids in showcasing intricate details of building designs.

Frequently Asked Questions (FAQs)

- How does laser cutting work?

- Laser cutting works by directing a high-powered laser at the material to be cut, melting, burning, or vaporizing it.

- What materials can be laser cut?

- Laser cutting is versatile and can be used on materials like wood, metal, acrylic, leather, and more.

- Is laser cutting environmentally friendly?

- Laser cutting can be more environmentally friendly than traditional methods due to reduced material waste.

- What file types are compatible with laser-cutting machines?

- Common file types include DXF, DWG, and AI, allowing for precise instructions to the laser cutter.

- How fast is the laser-cutting process?

- The speed of laser cutting depends on factors such as material thickness and intricacy of the design, but it is generally a swift process.

- Can laser cutting be used for mass production?

- Yes, laser cutting is suitable for mass production as it offers speed and accuracy.

- Is laser cutting cost-effective?

- While initial setup costs can be higher, the efficiency and precision often make laser cutting cost-effective in the long run.

- Are there limitations to laser cutting?

- Laser cutting has some limitations on material thickness, and certain materials may emit fumes during the process.

- How do you maintain a laser-cutting machine?

- Regular cleaning of optics and calibration are essential for maintaining the efficiency of a laser cutting machine.

- What safety measures should be taken when using laser-cutting machines?

- Safety measures include wearing protective gear, ensuring proper ventilation, and following manufacturer guidelines.