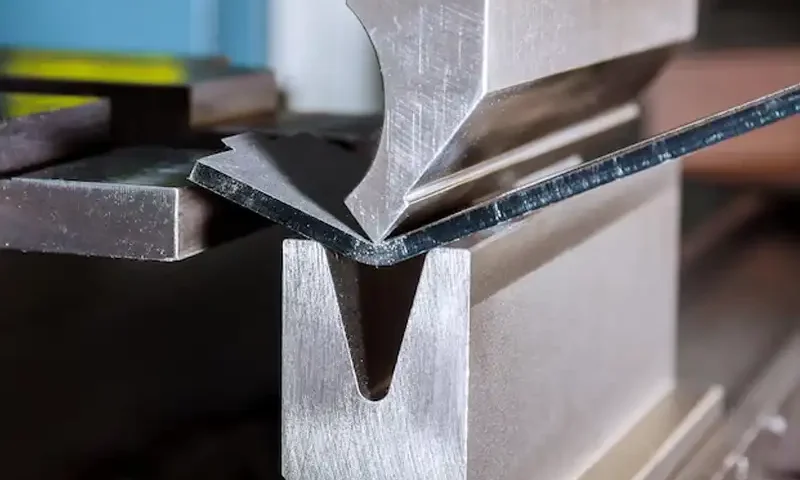

CNC Laser Bending: Precision and Efficiency in Metal Fabrication

April 25, 2025

Travel in Safety and Style with the Safar Ki Dua Car Hanging

May 15, 2025Introduction

In today’s fast-paced world, industries demand precision, efficiency, and cost-effectiveness. CNC bending services have revolutionized metal fabrication, offering unmatched accuracy for bending various metals like steel, aluminum, and copper. Whether you’re in automotive, construction, or manufacturing, CNC bending is a crucial tool for your metalwork needs.

What Makes CNC Bending Essential?

- Precision: CNC bending ensures exact angles and bends with minimal margin of error.

- Time Efficiency: Automated bending speeds up production times compared to manual methods.

- Cost-Effective: Reduces material waste and errors, saving both time and money.

Key Benefits of CNC Bending

- Unparalleled Accuracy

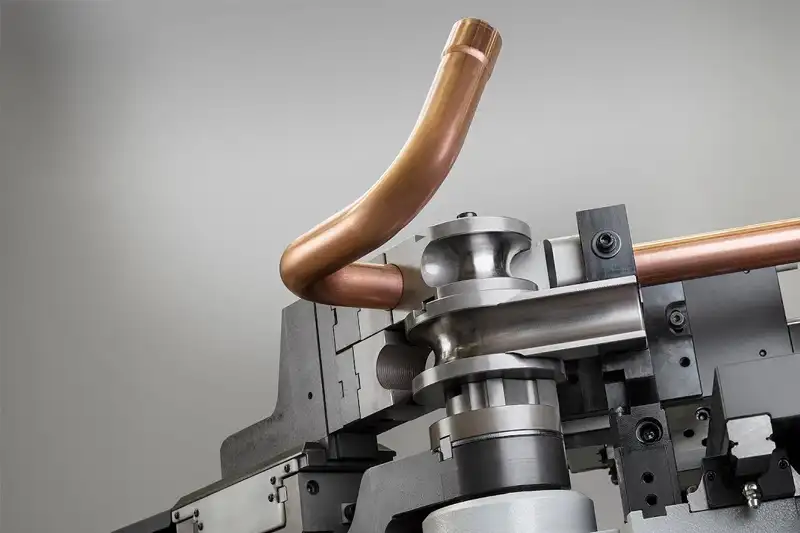

CNC bending machines operate with computer precision, ensuring the most accurate bends, even for complex designs. Whether you need sharp angles or smooth curves, CNC machines deliver consistent results every time. This level of precision is especially critical for industries like aerospace and automotive, where even small inaccuracies can compromise product safety and functionality. - Versatility Across Industries

CNC bending isn’t limited to just one type of project or industry. It’s used in creating components for:- Automotive Parts: For custom exhausts, brackets, and chassis.

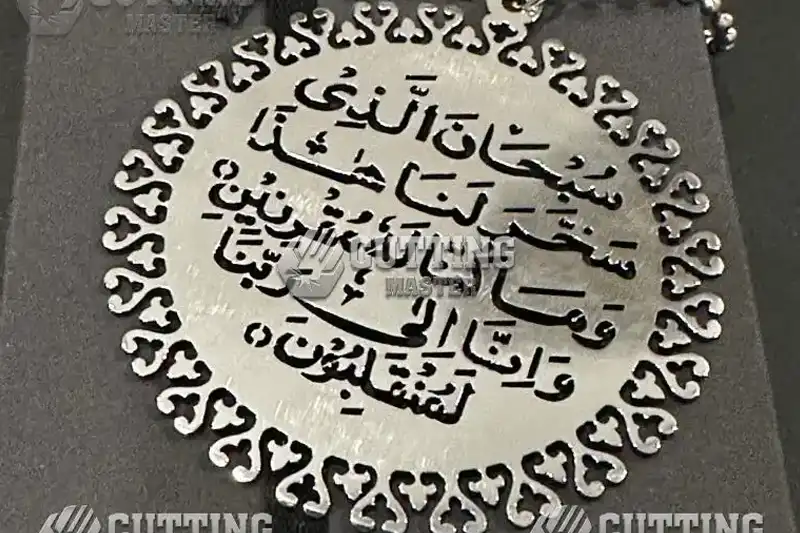

- Architectural Structures: Decorative metalwork and load-bearing structural elements.

- Manufacturing: Scalable production runs with minimal deviation between parts.

- Durability

Metal components produced with CNC bending maintain their structural integrity and are less likely to suffer damage or distortion during the bending process, making it an excellent choice for parts requiring long-term durability. - Custom Design Capabilities

CNC bending can accommodate unique, custom designs without sacrificing accuracy or consistency. Whether you need one prototype or a large production run, CNC bending can handle it. Its flexibility allows for tailored metal fabrication, which is crucial for businesses looking for bespoke solutions.

Example: CNC Bending in the Automotive Industry

A local automotive manufacturer leveraged CNC bending to produce custom exhaust systems for a new model. The precision and speed offered by CNC technology reduced manufacturing costs by 20% while delivering flawless components.

Our CNC Bending Process

At Cutting Master, our process begins with detailed specifications from the client. Using CAD software, we program the CNC machine to follow the exact design, ensuring that the bends are precise and consistent across each unit. This method eliminates human error and allows for scalability without sacrificing quality.

Related Service: CNC Bending Services

Explore how our Laser Cutting service complements CNC bending, providing a full range of metal fabrication solutions for all your industrial and creative needs.

FAQs

- What types of materials can CNC bending handle?

CNC bending works with metals such as steel, aluminum, brass, copper, and more. - Is CNC bending suitable for complex designs?

Yes, CNC bending can accommodate intricate designs with high precision and consistency. - How long does it take to complete a CNC bending project?

Turnaround times vary based on project size and complexity but are typically much faster than manual methods. - What industries benefit the most from CNC bending?

CNC bending is ideal for automotive, aerospace, construction, and industrial manufacturing. - Is there a minimum order quantity for CNC bending services?

No, we handle both small prototype orders and large-scale production runs.