The Advantages of Using Laser Cutting Services for Custom Projects

November 15, 2024

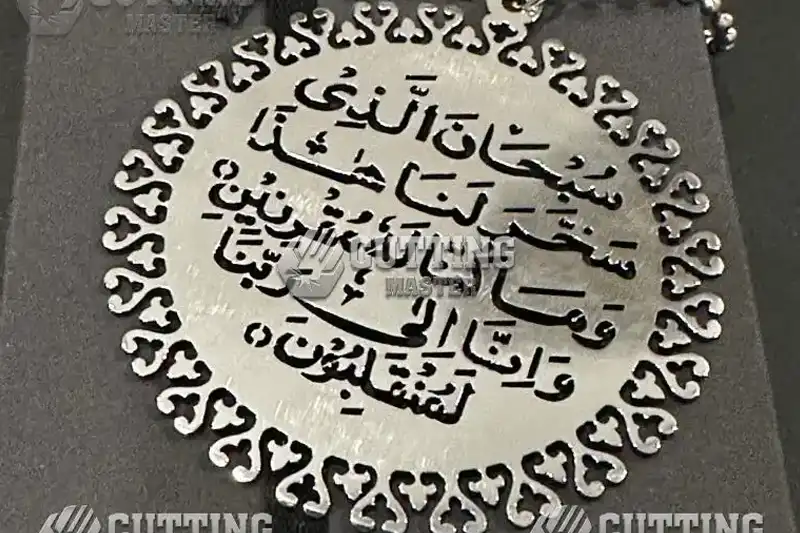

Elevate Your Car’s Interior with CuttingMaster’s Precision Laser-Cut Car Hanging Accessories

November 25, 2024Metal fabrication is at the heart of countless industries, transforming raw materials into functional and intricate products. Whether you’re in construction, automotive, aerospace, or any other sector requiring metal components, Cutting Master offers expert metal fabrication services that ensure quality, precision, and reliability. Discover how our comprehensive approach to metal fabrication can elevate your projects to the next level.

What is Metal Fabrication?

Metal fabrication is the process of building machines, structures, and other components from raw metal materials. It involves cutting, bending, welding, and assembling various metal pieces to create the desired product. This process is essential in industries where custom metal parts and structures are necessary for operations, construction, or product manufacturing.

The Metal Fabrication Process at Cutting Master

At Cutting Master, we pride ourselves on delivering high-quality metal fabrication services tailored to meet the specific needs of our clients. Here’s an overview of our process:

- Design and Planning: Our team works closely with you to understand your requirements and create detailed designs and blueprints for the metal components.

- Material Selection: We help you choose the best materials for your project, ensuring durability, performance, and cost-effectiveness.

- Cutting and Shaping: Using advanced techniques such as laser cutting, flame cutting, and CNC machining, we precisely cut and shape the metal according to your specifications.

- Welding and Assembly: Our skilled welders and fabricators then assemble the metal pieces, ensuring strong, reliable joints and structures.

- Finishing and Quality Control: We offer a variety of finishing options, including painting, powder coating, and polishing, to enhance the appearance and durability of the final product. Every piece undergoes rigorous quality checks to ensure it meets our high standards.

Why Metal Fabrication is Essential

Metal fabrication plays a crucial role in various industries by providing customized solutions that meet specific operational needs. Here’s why metal fabrication is indispensable:

- Customization: Metal fabrication allows for the creation of bespoke components tailored to the exact needs of your project or product.

- Durability: Fabricated metal components are built to withstand harsh conditions, ensuring longevity and reliability.

- Versatility: Metal fabrication can be applied to a wide range of materials and industries, from small parts to large structural elements.

- Cost-Efficiency: By fabricating custom metal parts, companies can reduce material waste and improve the efficiency of their operations.

Applications of Metal Fabrication

Metal fabrication is integral to numerous industries. Here are some of the most common applications:

- Construction: Fabricating structural beams, columns, and frames for buildings, bridges, and other infrastructure.

- Automotive: Creating custom parts, frames, and bodywork for vehicles and machinery.

- Aerospace: Fabricating precise components for aircraft, satellites, and other aerospace equipment.

- Manufacturing: Producing custom machinery, equipment, and tools required in various manufacturing processes.

- Renewable Energy: Building components for wind turbines, solar panels, and other renewable energy systems.

Why Choose Cutting Master for Metal Fabrication?

At Cutting Master, we combine advanced technology, skilled craftsmanship, and a commitment to quality to deliver metal fabrication services that exceed expectations:

- Experienced Team: Our fabricators bring years of experience and expertise to every project, ensuring precision and quality at every step.

- State-of-the-Art Equipment: We use the latest technology in cutting, welding, and finishing to deliver top-notch results.

- Comprehensive Services: From design to delivery, we manage every aspect of the metal fabrication process, providing a seamless and hassle-free experience for our clients.

- Quality Assurance: Every project undergoes thorough quality control checks to ensure that the final product meets your exact specifications and industry standards.

Case Study: Streamlining Manufacturing for an Automotive Client

One of our clients in the automotive industry required custom metal parts for a new line of vehicles. By partnering with Cutting Master, they received precisely fabricated components that met their strict specifications and timelines. Our ability to deliver high-quality parts quickly and efficiently allowed the client to streamline their manufacturing process and bring their new vehicles to market faster.

FAQs About Metal Fabrication

1. What materials can you work with in metal fabrication?

We work with a wide range of materials, including steel, aluminum, stainless steel, copper, and brass, to meet the diverse needs of our clients.

2. Can you handle both small and large-scale projects?

Yes, we cater to both small-scale custom projects and large-scale industrial fabrication needs, ensuring quality and precision regardless of the project size.

3. What types of finishing options do you offer?

We offer a variety of finishing options, including painting, powder coating, galvanizing, and polishing, to enhance the durability and appearance of your fabricated products.

4. How long does the metal fabrication process take?

The timeline varies depending on the complexity and size of the project. We provide an estimated lead time during the initial consultation and design phase.

5. Can you assist with the design phase of my project?

Absolutely! Our team works closely with you during the design phase to ensure that the final product meets your exact specifications and functional requirements.