Laser Cutting Business Mastery: Launching Your Venture in Pakistan

February 10, 2024

Exquisite Laser Cut Gate in Golden and Black Color: Elevate Your Entryway

February 29, 2024Discover how laser cutting is reshaping industries and unlocking new possibilities in design and manufacturing.

In the realm of modern manufacturing and design, one technology stands out for its precision and versatility – Laser Cutting. This revolutionary process has become the cornerstone of various industries, pushing the boundaries of what’s possible. In this article, we delve into the fascinating world of laser cutting, uncovering its mechanisms, applications, and the incredible impact it has on shaping the future.

Understanding Laser Cutting

Laser cutting is a high-precision method that utilizes a focused laser beam to cut through materials with incredible accuracy. Unlike traditional methods, laser cutting offers unmatched intricacy and detail, making it a game-changer in industries ranging from manufacturing to art and design.

Applications Across Industries

1. Manufacturing Marvels

Laser cutting has become the backbone of modern manufacturing. From intricate machine parts to complex prototypes, the technology ensures unparalleled precision, efficiency, and speed.

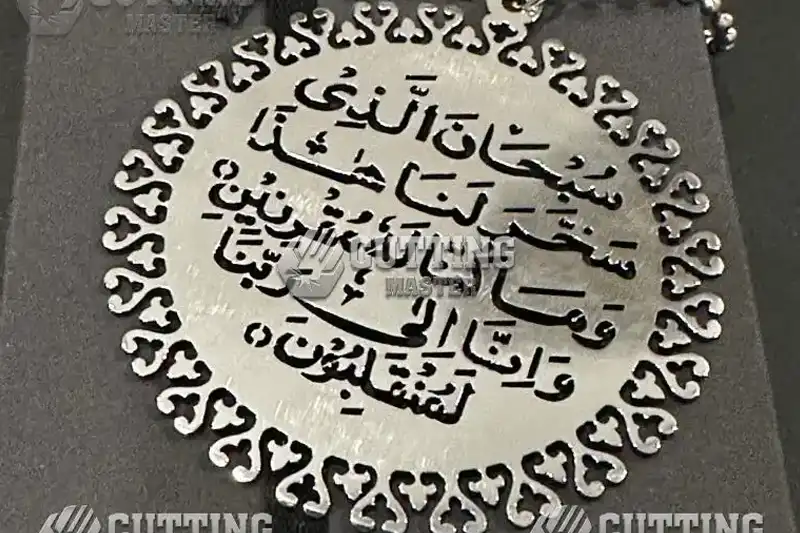

2. Artistic Expression

In the realm of art and design, laser cutting has opened up new possibilities. Artists and designers can now create intricate patterns, detailed sculptures, and custom pieces with ease, pushing the boundaries of creativity.

3. Architectural Advancements

Architects leverage laser cutting to bring their designs to life with unprecedented precision. From intricate facades to detailed scale models, the technology enhances the accuracy and intricacy of architectural elements.

The Laser Cutting Process

Laser cutting involves directing a high-powered laser at the material to be cut. The laser burns, melts, or vaporizes the material, leaving behind a clean, precise edge. The process is computer-controlled, allowing for intricate designs and shapes with minimal waste.

Advantages of Laser Cutting

- Precision: Laser cutting offers unmatched precision, allowing for intricate designs and complex patterns.

- Versatility: It can cut through a wide range of materials, including metal, wood, plastic, and more.

- Efficiency: The computer-controlled process ensures high efficiency and minimal material wastage.

FAQs About Laser Cutting

- What materials can be cut with laser cutting?

- Laser cutting is versatile and can cut through materials such as metal, wood, plastic, acrylic, and even fabrics.

- Is laser cutting suitable for large-scale manufacturing?

- Yes, laser cutting is widely used in large-scale manufacturing due to its precision and efficiency.

- How does laser cutting compare to traditional cutting methods?

- Laser cutting is more precise and allows for intricate designs compared to traditional methods.

- What safety precautions should be taken during laser cutting?

- Protective eyewear and proper ventilation are essential to ensure safety during laser cutting.

- Can laser cutting be used for engraving?

- Yes, laser cutting machines can also be used for engraving, adding a personalized touch to materials.

- What is the maintenance required for laser-cutting machines?

- Regular cleaning and calibration are necessary to maintain the efficiency of laser-cutting machines.

- Is laser cutting environmentally friendly?

- Laser cutting produces minimal waste, making it a more environmentally friendly option compared to some traditional cutting methods.

- Can laser cutting be used for 3D cutting and etching?

- Yes, laser cutting technology can be adapted for 3D cutting and etching, adding another dimension to the possibilities.

- What industries benefit the most from laser cutting?

- Industries such as manufacturing, aerospace, automotive, and art and design benefit significantly from laser cutting.

- Are there limitations to the thickness of materials that can be cut with laser cutting?

- While laser cutting is versatile, there are limitations to the thickness of materials it can effectively cut. The machine’s power and the type of material play a role in determining these limitations.