Flame Cutting: The Power of Precision for Heavy-Duty Applications

November 10, 2024

Metal Fabrication: Crafting Quality and Precision for Every Industry

November 20, 2024Introduction

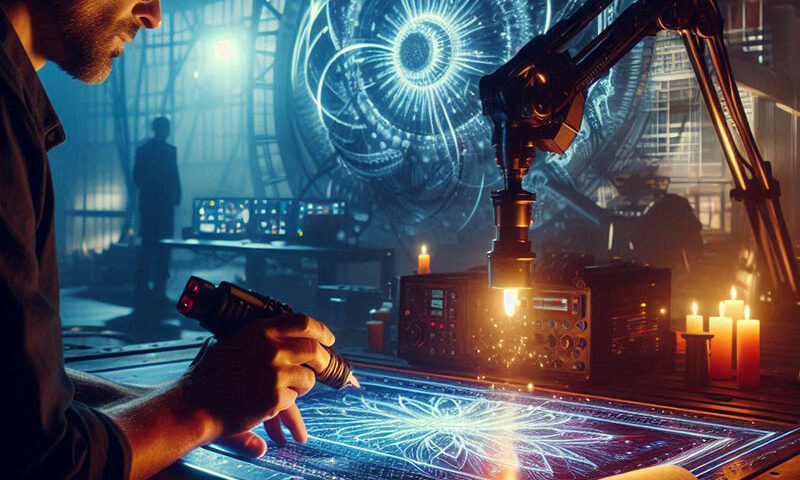

When it comes to custom projects, precision is non-negotiable. Laser cutting services provide businesses with the flexibility and accuracy needed to create intricate designs across various materials. In this article, we’ll highlight the key advantages of using laser cutting for your custom metal and non-metal projects.

Why Choose Laser Cutting for Custom Projects?

- Flexibility

Whether you’re cutting metal, wood, plastic, or glass, laser cutting offers unmatched versatility. It allows you to work with various materials without needing different cutting tools, making it an all-in-one solution for custom jobs. - Highly Detailed Designs

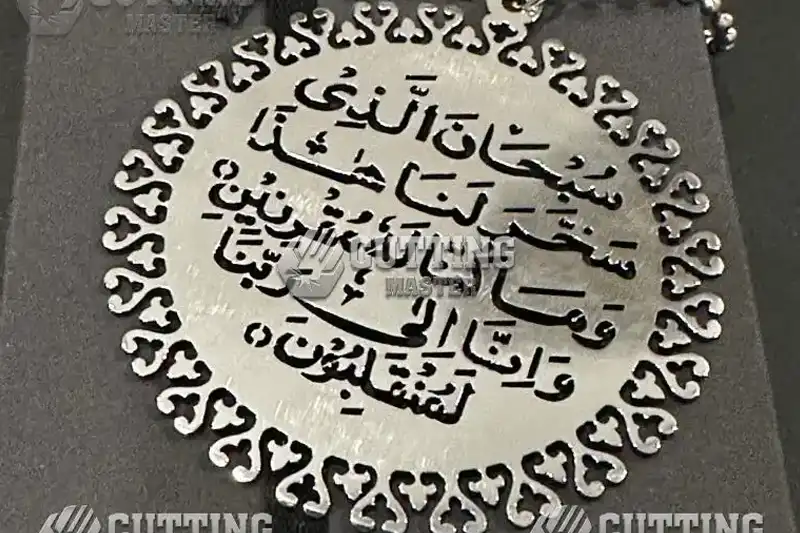

With laser cutting, the possibilities for intricate designs are endless. Whether it’s for decorative purposes or functional components, laser cutting can achieve the sharp, clean lines and details that traditional cutting methods cannot replicate. - Fast Turnaround Times

Laser cutting operates quickly and efficiently, making it perfect for businesses that need to meet tight deadlines without sacrificing quality. This is particularly useful for industries like architecture, where custom components are often required on short notice. - Minimal Waste

Laser cutting minimizes material waste, ensuring that every piece of metal or other material is utilized effectively. This cost-saving benefit is especially important for small businesses or custom projects that operate on tight budgets.

Example: Custom Architectural Metalwork

A local architectural firm recently commissioned custom metal facades for a commercial building. By using Eagle Machine Tools’ laser cutting services, they were able to achieve intricate designs with no material wastage, leading to a faster project completion time and lower costs.

Link to Related Services: Check Out Our Plasma Cutting Services

FAQs

- Can laser cutting handle complex designs for custom projects?

Yes, laser cutting is perfect for intricate, detailed designs across a range of materials. - What materials are suitable for custom laser cutting?

We can cut metals like steel, aluminum, and brass, as well as non-metals such as plastic and wood. - How long does a custom laser cutting project take?

The timeline depends on the complexity, but laser cutting is generally faster than traditional cutting methods. - What industries can benefit from custom laser cutting?

Architecture, automotive, manufacturing, and even the creative arts benefit from laser cutting services. - How much waste does laser cutting produce?

Laser cutting produces minimal waste, making it an environmentally friendly and cost-effective choice.