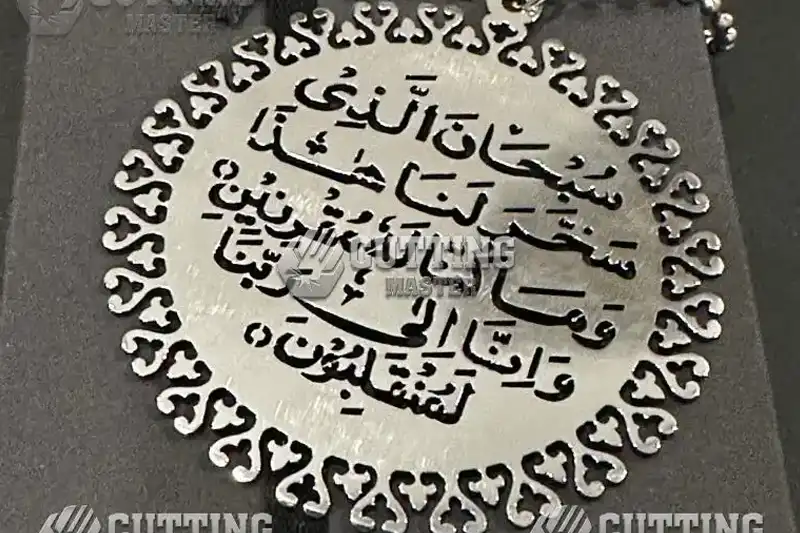

Kalma Car Hanging Accessories | Laser Cutting

October 5, 2023

Elevate Your Car’s Interior with Ayatul Kursi Laser-Cut Car Hanging Accessories

October 14, 2023The Impact of Laser Cutting Technology on Modern Industry

Laser-cutting technology has swiftly carved its way into the heart of the modern industry, leaving an indelible mark on manufacturing, engineering, and design. The precision and versatility of laser-cutting machines have catalyzed innovations across various sectors, elevating the standards of productivity, efficiency, and product quality. In this article, we will delve into the profound impact of laser-cutting technology on contemporary industry and explore how it continues to revolutionize the way we create and manufacture.

The Evolution of Laser Cutting

Laser cutting, as we know it today, has come a long way since its inception. Originally developed in the 1960s for industrial applications, this technology has seen continuous advancements and refinements. The core principle remains the same: a high-powered laser beam is focused to cut or engrave materials with pinpoint accuracy.

However, the equipment, software, and the range of materials that can be processed have all undergone significant enhancements. These developments have made laser-cutting machines more accessible, versatile, and efficient than ever before.

A Multifaceted Impact

Laser cutting’s influence extends across a multitude of industries, each reaping the benefits of this innovative technology:

1. Automotive Manufacturing:

- Laser-cut components are integral to modern vehicles, from precise body panels to intricate engine parts. This technology has streamlined the automotive manufacturing process, improving efficiency and the overall quality of vehicles.

2. Aerospace Engineering:

- In the aerospace industry, where precision is non-negotiable, laser cutting ensures the creation of lightweight yet robust components. This not only enhances fuel efficiency but also contributes to the safety of air travel.

3. Electronics and Microfabrication:

- The world of electronics relies on laser cutting for delicate operations like PCB (Printed Circuit Board) manufacturing. This technology is instrumental in producing miniature yet intricate components for our electronic devices.

4. Medical Devices:

- Laser-cut parts play a vital role in the production of medical devices, from surgical instruments to implants. The precision of laser cutting is essential in the healthcare industry.

5. Architectural Design:

- In architectural and interior design, laser cutting enables intricate detailing and intricate patterns in construction materials like steel, glass, and wood. This has pushed the boundaries of design possibilities.

The Advantages of Laser Cutting

The widespread adoption of laser cutting technology can be attributed to a host of advantages:

1. Unmatched Precision:

- Laser cutting offers unprecedented precision, allowing for intricate designs and complex geometries. This precision is critical in industries where the smallest error can lead to product failure.

2. Versatility:

- Laser cutting can be applied to a wide range of materials, including metals, plastics, ceramics, composites, and more, making it adaptable to various industrial needs.

3. Speed and Efficiency:

- Laser cutting is not only precise but also remarkably fast, reducing production time and costs. This speed is particularly beneficial for high-volume manufacturing.

4. Minimal Material Waste:

- Laser cutting is a non-contact process, minimizing wear on cutting tools and reducing material waste. This aligns with modern sustainability goals.

5. Complex Designs:

- Laser-cutting technology makes it possible to create intricate and highly detailed designs that may be challenging or impossible to achieve with traditional machining methods.

Frequently Asked Questions (FAQs)

Q1: How safe is laser cutting technology for operators and the environment?

A1: Laser-cutting technology is generally safe when used correctly. Operators should follow safety protocols and wear appropriate protective gear. The environmental impact is relatively low, as it reduces material waste and energy consumption.

Q2: Are there limitations to the materials that can be cut with laser cutting technology?

A2: Laser cutting is versatile, but the choice of laser source (CO2, fiber, Nd:YAG, etc.) and power should match the material’s properties. Some materials may be challenging to cut due to high reflectivity or heat sensitivity.

Q3: Can laser-cutting machines accommodate large-scale production needs?

A3: Yes, laser cutting machines can handle large-scale production, but the choice of machine should align with the production volume and speed requirements. Fiber laser machines, in particular, are known for their efficiency in high-volume production.

Q4: Is laser cutting technology suitable for small businesses and startups?

A4: Absolutely. Laser-cutting technology is available in various sizes and price ranges, making it accessible to small businesses and startups. It offers the flexibility to start small and scale up as the business grows.

Q5: How has laser cutting contributed to sustainability in modern industry?

A5: Laser cutting reduces material waste, increases energy efficiency, and minimizes the environmental impact. It aligns with the growing trend towards sustainable and eco-friendly manufacturing practices.

Conclusion

The impact of laser-cutting technology on modern industry is profound and continues to evolve. From the automotive assembly line to the intricacies of medical device production, laser cutting has become a symbol of precision, efficiency, and innovation.

As the industry continues to embrace sustainable practices and the demands for intricate designs and precision components increase, laser-cutting technology is poised to play an even more significant role in shaping the future of manufacturing.

In a world where precision and efficiency are paramount, laser-cutting technology stands as a beacon of progress, guiding industries toward excellence.