Transform Your Designs with CuttingMaster: A Complete Guide to Precision Tools & Products

October 25, 2024

Flame Cutting: The Power of Precision for Heavy-Duty Applications

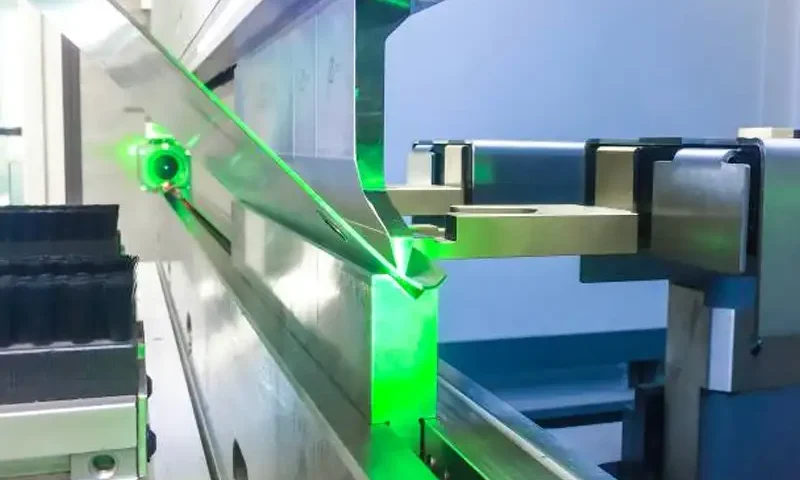

November 10, 2024If you’re looking for precision and efficiency in metal fabrication, CNC bending is the solution you need. Here’s why it’s indispensable for industrial projects.

Advantages of CNC Bending

- Unmatched Precision: Achieve exact bends every time.

- Time-Saving: Quick turnaround for large-scale projects.

- Cost-Effective: Reduces errors and minimizes material wastage.

Industries That Benefit from CNC Bending

- Manufacturing: Ensures consistency in production.

- Aerospace: High-precision parts for safe, reliable performance.

- Automotive: Durable and perfectly shaped components.

CNC Bending in Action

A recent automotive project required precisely bent aluminum parts for a new model. CNC bending cut production time in half and improved component reliability.

Link to Related Services: Bending Services in Pakistan

FAQs

- What’s the accuracy of CNC bending?

CNC machines offer precision within fractions of a millimeter. - Can CNC bending handle heavy-duty materials?

Yes, it’s capable of bending thick metals like steel. - How does CNC bending compare to traditional methods?

It’s faster, more accurate, and reduces human error. - What are the setup costs for CNC bending?

While higher than manual methods, the long-term savings make it worthwhile. - What industries use CNC bending the most?

Automotive, aerospace, and construction are major industries that rely on CNC bending.