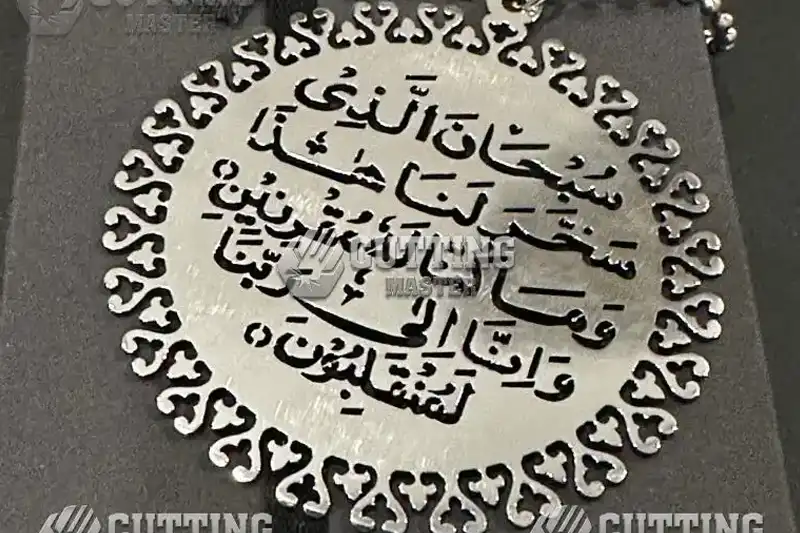

Laser-Cut Darood Car Hanging: A Symbol of Blessings and Protection for Every Journey

September 10, 2024

Fiber Laser Cutting: Precision and Efficiency at Its Best

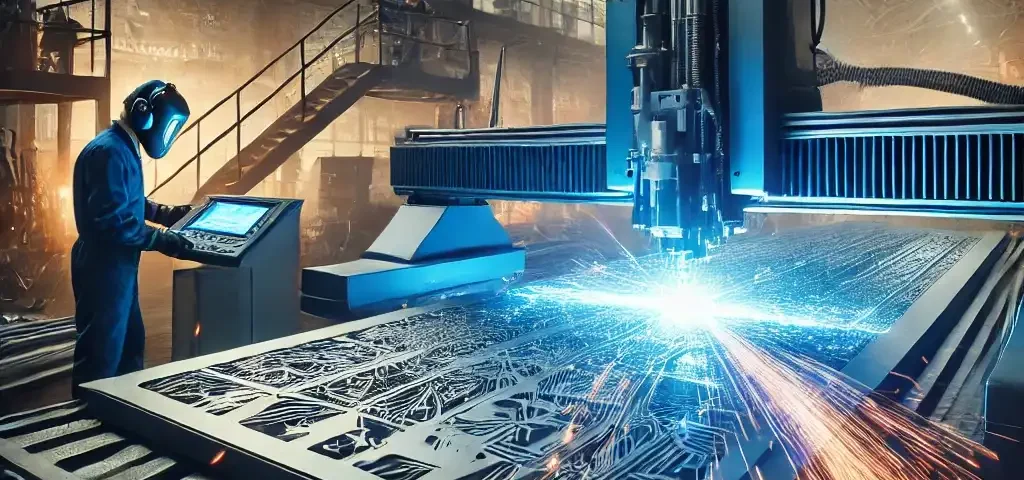

September 28, 2024Plasma cutting is one of the most powerful and versatile tools in modern metal fabrication. If you’re looking for a precise, efficient, and cost-effective way to cut through metals like steel, aluminum, and copper, plasma cutting is the ultimate solution. At Cutting Master, we specialize in delivering high-quality plasma cutting services that cater to both industrial and creative needs.

Whether you’re working on a large-scale construction project or creating intricate metal art, our plasma cutting technology ensures accuracy and speed, making it the go-to option for clients across various industries. Let’s dive into why plasma cutting is a game-changer and why Cutting Master should be your first choice for all your metal fabrication needs.

What is Plasma Cutting?

Plasma cutting is a process that uses a high-velocity jet of ionized gas (plasma) to cut through electrically conductive materials. The plasma is created by heating the gas with an electric arc. This technique is effective for cutting a wide range of metals, including:

- Steel

- Stainless Steel

- Aluminum

- Brass

- Copper

The plasma cutter directs the plasma jet toward the metal, melting it and blowing away the molten material, leaving a clean, precise cut.

Why Choose Plasma Cutting?

There are several reasons why plasma cutting is an ideal choice for metal fabrication projects:

- High Precision

Plasma cutting allows for sharp, intricate cuts with minimal heat-affected zones, ensuring that the metal retains its structural integrity. - Speed and Efficiency

Plasma cutting is significantly faster than traditional cutting methods, reducing production times and increasing efficiency. This makes it perfect for projects requiring quick turnarounds. - Versatility

Plasma cutting works with a variety of materials and thicknesses, making it suitable for multiple industries, from automotive and aerospace to art and architecture. - Cost-Effective

The precision and speed of plasma cutting reduce waste and material costs, providing an economical solution for metal fabrication. - Smooth Edges

Plasma cutting produces smooth, high-quality edges, minimizing the need for additional finishing processes like grinding or sanding.

Applications of Plasma Cutting

Plasma cutting has a wide range of applications across various industries. At Cutting Master, we have the expertise to handle diverse projects, including:

- Custom Metal Fabrication: Plasma cutting is perfect for creating custom metal pieces for machinery, equipment, and industrial components.

- Construction and Structural Work: Plasma cutting is commonly used for cutting steel beams, pipes, and other structural elements in construction.

- Automotive Industry: The precision and speed of plasma cutting are highly valued in automotive manufacturing and repair work, where complex shapes and high tolerances are required.

- Art and Design: Plasma cutting is also a preferred technique for creating intricate metal designs, sculptures, and decorative elements like wall panels and gates.

- Aerospace Industry: In aerospace, plasma cutting is used to cut aluminum and other lightweight metals for aircraft parts, where precision is critical.

Why Choose Cutting Master for Plasma Cutting?

At Cutting Master, we pride ourselves on delivering top-quality plasma cutting services. Here’s why we stand out:

- State-of-the-Art Equipment

We use advanced plasma cutting machines that ensure precision, speed, and efficiency, no matter the complexity of your project. - Experienced Team

Our team of skilled professionals has years of experience in metal fabrication and cutting, ensuring that every project meets the highest standards of quality. - Custom Solutions

We work closely with our clients to provide tailored solutions that meet their specific needs. Whether you need one-off custom pieces or high-volume production, we have you covered. - Affordable Rates

We offer competitive pricing without compromising on quality, making our plasma cutting services accessible for businesses of all sizes. - Fast Turnaround

With our efficient processes and equipment, we can complete projects quickly, ensuring you meet your deadlines.

Materials We Cut

At Cutting Master, our plasma cutting services cater to a wide range of materials, including:

- Mild Steel

- Stainless Steel

- Galvanized Steel

- Aluminum

- Brass

- Copper

No matter the material or thickness, our plasma cutting machines are capable of producing clean, precise cuts.

The Cutting Master Difference

Cutting Master is your trusted partner for high-quality metal fabrication. We’re committed to delivering plasma cutting services that exceed expectations, and our team is dedicated to ensuring your project is completed to perfection. Whether you’re a designer, contractor, or artist, our plasma cutting solutions are tailored to your unique needs.

Ready to Get Started?

If you have a project in mind, contact us today to discuss your plasma cutting needs. Our team is here to help you bring your designs to life with precision and professionalism. Visit our services page to learn more about our capabilities and how we can assist you.

FAQs

1. What is plasma cutting?

Plasma cutting uses a high-temperature plasma jet to cut through metal with precision and speed, suitable for various applications in different industries.

2. What materials can be cut with plasma cutting?

Common materials include steel, stainless steel, aluminum, brass, and copper.

3. Is plasma cutting cost-effective?

Yes, plasma cutting reduces waste, increases efficiency, and minimizes the need for secondary finishing, making it a cost-effective solution.

4. Can plasma cutting handle large projects?

Yes, plasma cutting is ideal for both small-scale custom jobs and large industrial projects.

5. How quickly can my project be completed?

At Cutting Master, we pride ourselves on fast turnarounds while maintaining high-quality standards, ensuring your project meets its deadlines.