Unlock Precision with CNC Bending: Transform Your Projects Today!

October 5, 2024

Transform Your Designs with CuttingMaster: A Complete Guide to Precision Tools & Products

October 25, 2024Introduction

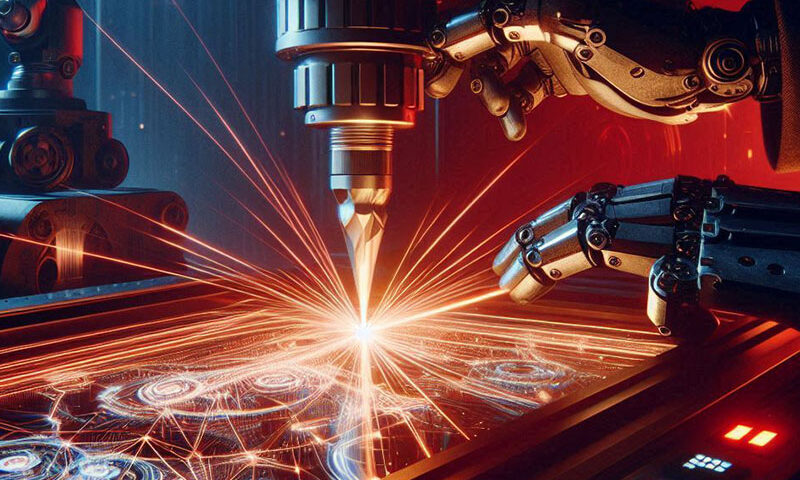

Laser cutting services have revolutionized the metal fabrication industry, offering unparalleled precision, speed, and efficiency. Whether you’re in manufacturing, automotive, or construction, laser cutting provides high-quality results that can transform your projects. In this article, we’ll explore how laser cutting technology works and why it’s an essential service for businesses looking to stay ahead.

How Laser Cutting Works

Laser cutting uses a focused laser beam to cut, etch, or engrave materials with extreme accuracy. The process is controlled by a computer (CNC), which ensures every cut is precise down to the millimeter. By using high-intensity lasers, materials like steel, aluminum, brass, and copper can be shaped without any manual intervention. The result? Smooth edges, complex shapes, and consistent quality.

Advantages of Laser Cutting

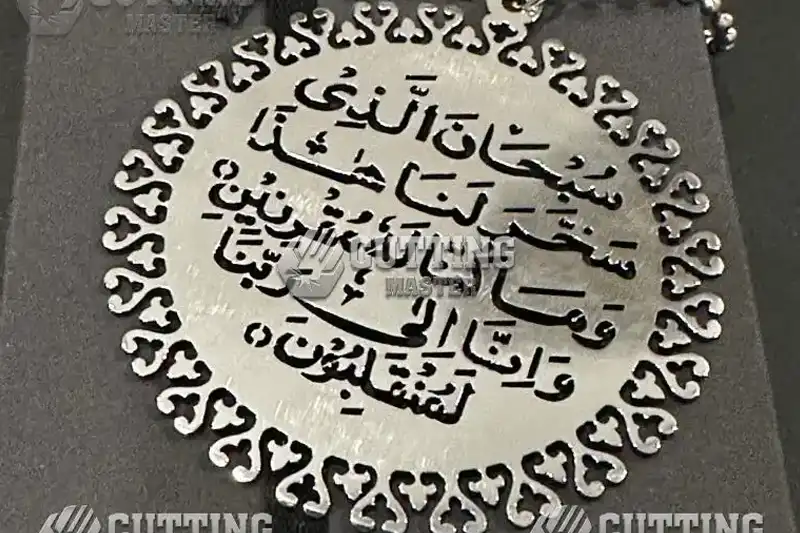

- Precision and Accuracy

The high-precision technology used in laser cutting allows for intricate designs that traditional cutting methods can’t achieve. This is particularly useful in industries that require fine details, such as jewelry or architectural design. - Speed and Efficiency

Laser cutting is significantly faster than manual cutting or other automated methods. This makes it the go-to choice for businesses that need quick turnaround times without compromising quality. - Versatility Across Materials

Laser cutting is not limited to just metals. It can cut plastics, glass, wood, and even ceramics. This makes it highly versatile for industries ranging from construction to custom product design. - Cost-Effectiveness

While laser cutting might have a higher initial cost, its precision reduces material wastage, making it more economical in the long run.

Case Study: Laser Cutting in the Automotive Industry

A local automotive company needed high-precision metal components for a new vehicle model. By using laser cutting services from Eagle Machine Tools, they reduced production time by 30% and saw a significant improvement in product quality.

Link to Related Services: Explore Our CNC Bending Services

FAQs

- What types of materials can be cut using laser technology?

Laser cutting works with metals like steel, aluminum, brass, copper, and even non-metal materials like plastics and wood. - How precise is laser cutting?

It offers precision down to fractions of a millimeter, making it ideal for intricate designs. - Is laser cutting cost-effective for small projects?

Yes, it’s highly efficient, even for small-scale projects, due to minimal material waste. - Can laser cutting be used for custom designs?

Absolutely! The CNC programming allows for unique, complex designs to be created with ease. - How fast is the laser cutting process?

Laser cutting is significantly faster than traditional methods, making it ideal for quick production runs.